Fried onions, with their crispy texture and rich flavor, are a popular ingredient in many culinary dishes worldwide. Whether it’s adding a savory crunch to salads, soups, or main courses, or simply as a delicious garnish, fried onions are a versatile and tasty addition to any meal. While homemade fried onions are a common kitchen task, producing them on a larger scale in a factory setting involves a systematic process from start to finish. Let’s delve into how to make fried onions in factory.

1. Raw material selection:

Quality raw onions are the foundation of exceptional fried onions. Varieties such as yellow, white, or red onions are commonly used. They should be firm, fresh, and free from blemishes or signs of decay.

2. Cleaning and peeling:

Onions are thoroughly washed to remove dirt and debris. In industrial settings, automated machinery can efficiently peel the onions, removing the outer layers without damaging the flesh. This step ensures consistency and saves time compared to manual peeling.

3. Slicing:

After peeling, the onions are sliced into uniform thickness to ensure even frying. Industrial slicers are employed for this task, capable of slicing large quantities quickly and precisely.

4. Pre-frying:

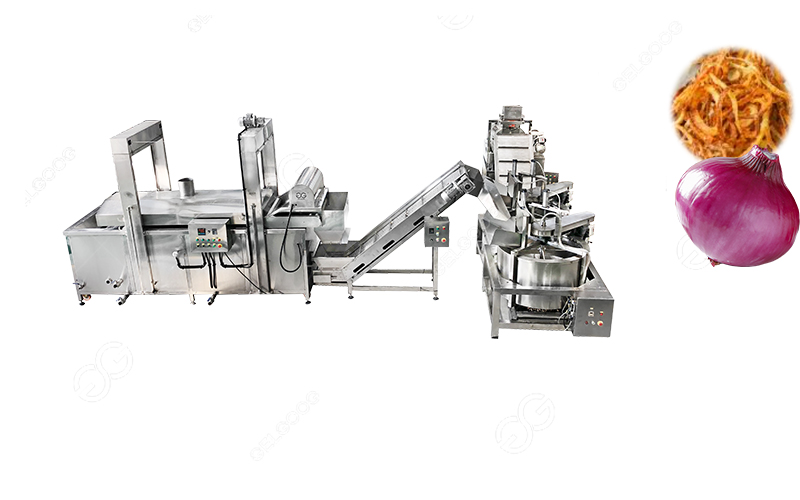

To achieve the desired texture and flavor, the sliced onions undergo a pre-frying process. They are typically immersed in hot oil for a short period, allowing them to partially cook and develop a golden color. This step also removes excess moisture from the onions, enhancing crispiness and extending shelf life.

5. Cooling and de-oiling:

After pre-frying, the onions are transferred to a conveyor belt or mesh screen to cool and drain excess oil. Industrial centrifuges or vibrating screens may be used to remove excess oil, ensuring the final product is not greasy.

6. Final frying:

Once cooled and de-oiled, the onions undergo the final frying process. They are immersed in hot oil at a higher temperature than the pre-frying stage, allowing them to crisp up and achieve the desired golden-brown color. This step is crucial for imparting the characteristic crunch and flavor associated with fried onions.

7. Seasoning:

Depending on the desired flavor profile, the fried onions may be seasoned with salt, spices, or other flavorings. Seasoning can occur either during the final frying stage or immediately after frying while the onions are still warm and receptive to flavor absorption.

8. Cooling and packaging:

After frying and seasoning, the fried onions are cooled to room temperature to preserve their crispness. They are then carefully packaged in airtight containers or bags to maintain freshness and prevent moisture absorption. Packaging may involve automated filling and sealing machines to ensure efficiency and product integrity.

9. Quality control:

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure consistency and adherence to food safety standards. Samples are regularly tested for flavor, texture, and overall quality to meet consumer expectations.

10. Storage and distribution:

Once packaged, the fried onions are stored in a cool, dry environment to maintain their quality. They are then distributed to retailers, restaurants, or foodservice providers according to demand.

Manufacturing fried onions in a factory setting involves a precise and systematic process from raw material selection to packaging and distribution. By following these steps meticulously, producers can consistently deliver high-quality fried onions that satisfy consumer preferences and culinary requirements. If you want to start onion processing business, we can provide you the fried onion processing line.